| Project name | Injection Molding |

| Project Title | Injection Molding Process Design of Multi-Functional Electrolyte |

| Abstract | Multi-functional electrolytes (MFEs) are a critical component in the development of energy storage solutions for modern energy demands. Professor Caiwei Shen of the University of Massachusetts Dartmouth performs research toward the creation of Structural Supercapacitors (SSC) that require the MFE to function. The fabrication of the MFE is comprised of Polyethylene Terephthalate (PET) and Lithiumbis(trifluoromethanesulfonyl)imid (LiTFSI). In order to achieve a favorable MFE, mechanical and electrical properties should be maximized without negatively impacting the SSC. To assure the homogeneity of the MFE, it was determined that injection molding would be the selected manufacturing process. However, due to complexity within the process design, the IMPD team was commissioned to deliver solutions for a myriad of stakeholder coupon requirements and processing parameters.

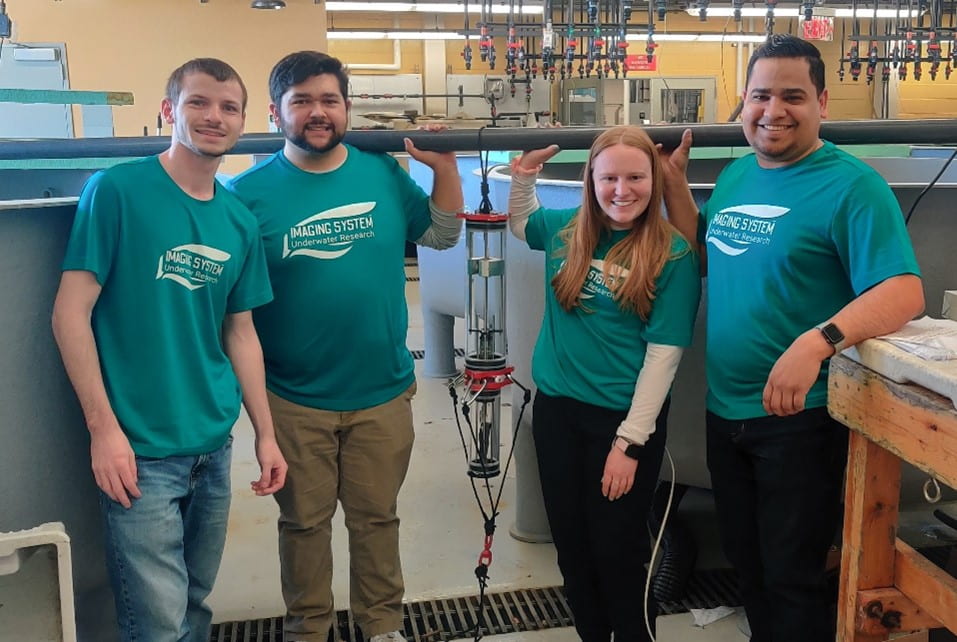

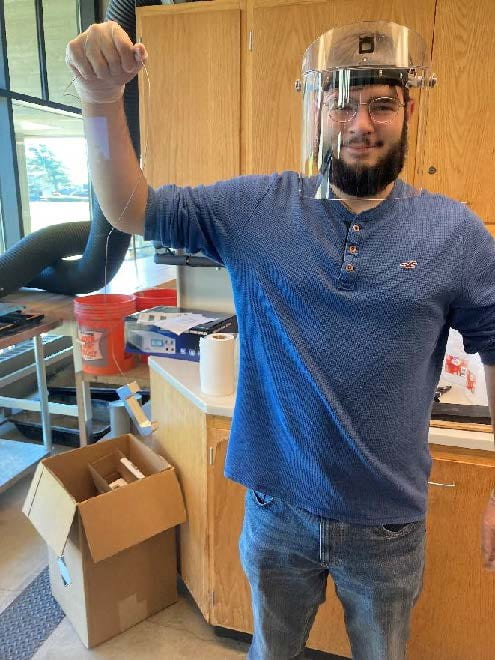

The three main requirements posed by the stakeholders include the following: 1. A portable fabrication cell regulating humidity levels to 30% RH 2. A temperature-controlled fixture for varying mold types 3. Optimized processing parameters of MFE with support data The IMPD team was able to deliver customized fabrication equipment and process design work instructions that would support research activities into the future state. The IMPD team developed conceptual designs for a glovebox designated 1.1 to house the AB100 injection molding equipment. In addition, a desiccant drying system was integrated to supply treated facility air into the control environment with reduced RH levels and low particulate counts. It was determined that to meet project timeline expectations that the fabrication of 1.1 would be sourced to a 3rd party manufacturer. The decision to outsource fabrication was supported by a supplied certificate of compliance which guaranteed the equipment’s functionality. The portability of 1.1 was achieved through the acquisition of a prefabricated cart to which the glovebox and desiccant dryer were fixed. Subsequent testing revealed that levels of 14% RH were achieved, exceeding stakeholder requirements. The temperature control fixture designated 1.2 featured customized molding solutions for the AB100 equipment. The IMPD design engineers employed engineering principles of fluid dynamics, heat transfer, and material science to effectively design an insert molding fixture. The fixture features 2 heating cartridges wired in parallel to a voltage controller that receives active feedback from a standard thermocouple to regulate heating cycles. In addition, the fixture features ported channeling for liquid cooling upgrades. The IMPD team achieved stable temperature control at 180°C, allowing for optimized cavity pack-out. The interchangeable insert cavity allows for quick processing rates, and low-cost cavity alterations increase net productivity. For deliverable 3, a design of experiments was developed to actively fabricate MFE coupons. A subsequent work instruction was developed which outlined the processing parameters required for fabrication. Next, each technician performed a series of experimentation featuring 5 trials. These results were documented and evaluated to supply the stakeholder with optimum processing parameters based upon compositions that range from 100%-PET to 70% -PET + 30%-LiTFSI compositions. It was found that the process design was capable and repeatable throughout all compositions. In conclusion, the IMPD team fulfilled or exceeded the criteria set forth by the stakeholders. In the future state, it has been recommended to the stakeholders that a preventative maintenance schedule should be developed to support the process design supplied. In addition, the exchange of material compositions should be evaluated for use within this custom molding solution to ensure effectiveness. |

| Faculty advisor | Dr. Caiwei Shen |

| Sponsor | Dr. Caiwei Shen |

| Team lead | Roger Tessier |

| Team Members | Anthony Lazzareschi, Christophe Chedid, Mario Farah |

| Video link | https://youtu.be/7aLQOMytCic |